How to Choose the Best Cooler Panels for Your Needs?

When it comes to selecting cooler panels, the options can be overwhelming. Cooler panels are essential for maintaining temperature control in various environments. They play a crucial role in both residential and commercial settings. Choosing the right type can greatly influence efficiency and cost.

Consider the material of the cooler panels. Different materials have varied insulation properties. Foam panels, for example, are lightweight and offer good thermal resistance. On the other hand, metal panels may provide durability but can conduct heat. Think about where you'll use them too. Indoor and outdoor settings may require different features.

It's also vital to reflect on the size and thickness of the cooler panels. Not all panels fit every space perfectly. Identify the specific dimensions required for your project. A mismatch may lead to increased energy costs. Ultimately, it’s about balancing performance and practicality. Exploring the best cooler panels can lead to a more efficient and effective temperature management system. Don't rush; take your time to analyze the options.

Factors to Consider When Selecting Cooler Panels

When selecting cooler panels, several factors come into play. Insulation efficiency is crucial. Look for panels with high R-values, which indicate effective temperature retention. Thicker panels typically offer better insulation. Also, consider the material. Options include polyurethane, polystyrene, or fiberglass. Each has its pros and cons.

Installation is another key point. Some panels may require professional help, which adds to the cost. Easy-to-install panels can save time and money. Durability matters too. Pick panels resistant to moisture, corrosion, and extreme temperatures.

Aesthetics shouldn't be overlooked either. Color and finish might impact your space's vibe. Compatibility with existing structures also matters. Inadequate fitting can cause air leaks and inefficiency. Reflect on your needs carefully. Often, what seems like a small choice can lead to major consequences down the line.

Types of Cooler Panels and Their Features

Choosing the right cooler panels can significantly enhance your cooling experience. When considering different types of cooler panels, it’s essential to focus on their material and efficiency. Common materials include polyurethane, polystyrene, and fiberglass. Each has a unique insulating capability. Polyurethane panels are known for excellent thermal performance. Fiberglass is lightweight and corrosion-resistant, making it ideal for various environments.

The thickness of cooler panels also plays a vital role. Thicker panels offer better insulation, leading to prolonged cooling. However, they may add weight to your cooler. If mobility is a concern, lighter options may be more suitable. Additionally, the panel's surface finish can affect durability. Smooth surfaces are easier to clean, while textured finishes can provide extra grip.

You might find it challenging to balance insulation and weight. This requires thoughtful consideration. Knowing your specific needs helps to narrow down your choices. For example, if you prioritize portability, opt for thinner panels. If you often face extreme temperatures, go for thicker, insulated options. You will need to reflect on your priorities and make trade-offs. This decision can profoundly impact your overall satisfaction with the cooler's performance.

Comparison of Different Types of Cooler Panels

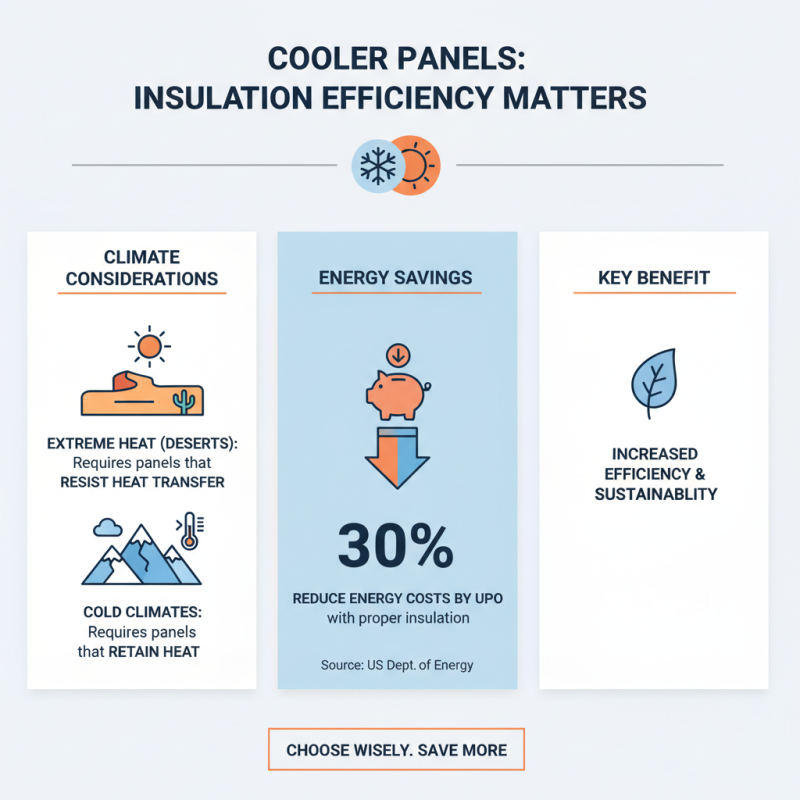

Assessing Insulation Efficiency for Your Climate

When choosing cooler panels, insulation efficiency is crucial. Different climates demand different insulation properties. For instance, in regions with extreme heat, such as deserts, you need panels that resist heat transfer effectively. According to the Department of Energy, a well-insulated space can reduce energy costs by up to 30%.

Material choice greatly influences insulation performance. Polystyrene panels offer decent R-values, but polyisocyanurate panels are more efficient, especially in hot climates. R-value measures resistance to heat flow. Higher R-values indicate better insulation. Research shows that for every increase of R-5, cooling costs can decrease by nearly 10%. Such data is vital when contemplating energy expenditures.

Yet, selecting the best insulation isn't always straightforward. Miscalculating your local climate's needs can lead to suboptimal decisions. In humid areas, for example, insulation must also manage moisture to prevent mold. Understanding specific requirements is essential for effective insulation. Striking the right balance ensures energy efficiency and comfort, but it requires careful analysis.

Evaluating Durability and Maintenance Requirements

When selecting cooler panels, durability is a key factor. Different materials offer varying levels of strength and resistance to wear. Some panels are made from thick, insulated materials, which may provide better longevity but can be heavier. Others might be lighter and more flexible, yet they could wear out faster. Consider how often you plan to use them and in what conditions. If you're moving them frequently, lighter panels may suit your needs.

Maintenance is another vital aspect to consider. Some panels require regular cleaning and upkeep to retain their effectiveness. Simple routines, like wiping down the surfaces, can prolong their life. Others might be more resistant to elements, reducing maintenance needs. However, neglecting a maintenance schedule could lead to premature failures. It’s crucial to assess how much time and effort you're willing to invest in upkeep. Making the right choice now can save you from headaches later on.

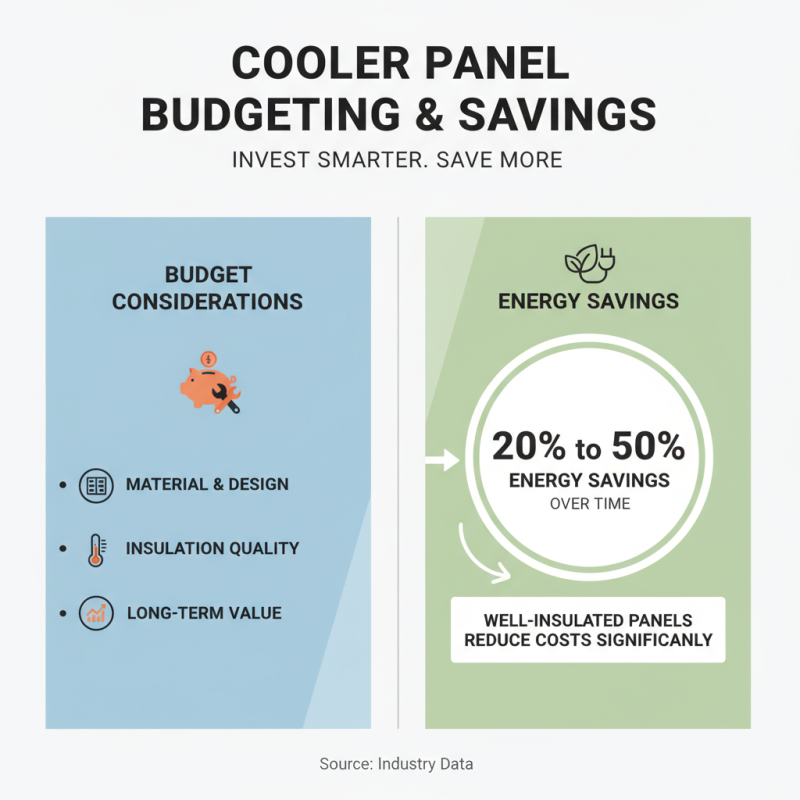

Cost Considerations and Budgeting for Cooler Panels

When budgeting for cooler panels, it's crucial to consider various factors. Industry data shows that well-insulated panels can save energy costs significantly. Depending on the material and design, you could see energy savings of 20% to 50% over time. This can transform your budget requirements.

Material choices heavily influence costs. For example, polystyrene panels typically cost $2 to $5 per square foot. In contrast, polycarbonate panels can range from $4 to $10 per square foot. Understanding the longevity and efficiency of materials is essential. A cheap option may seem attractive initially but could lead to higher expenses in energy bills or replacements later.

Installation costs also factor in. Professional installation can add $1 to $3 per square foot. DIY options can offer savings, but be cautious. Mistakes during installation may end up costing more. It's a balancing act. Assess your skills and budget before making a decision. Always crunch the numbers carefully.

Related Posts

-

Understanding Cooler Panels: The Key to Energy Efficiency in Modern Refrigeration Systems

-

Revolutionize Your Space: The Ultimate Guide to Innovative Cooler Panels for Every Need

-

Future of Freezer Panels Industry Highlighted at the 138th China Import and Export Fair in 2025

-

What are Freezer Panels and How Do They Revolutionize Temperature Control

-

Top 10 Benefits of Cladding Panels for Modern Architecture and Design

-

10 Essential Tips for Choosing the Best PVC Doors Based on Market Trends and Expert Insights