10 Essential Facts About Cladding Sheet You Need to Know

Cladding sheets have become a pivotal component in modern architecture and construction, offering both aesthetic appeal and functional advantages. According to a report by MarketsandMarkets, the global cladding market is expected to reach $304.2 billion by 2027, driven by the increasing demand for sustainable and energy-efficient building materials. Cladding sheets serve not only to enhance the exterior appearance of buildings but also to improve insulation and protect against weather elements. With advancements in technology and material science, these sheets are now available in various types, including metal, wood, vinyl, and composite, each catering to specific design requirements and environmental considerations. Understanding the essential facts about cladding sheets is crucial for architects, builders, and contractors aiming to make informed decisions in their projects and contribute to more resilient and visually appealing infrastructures.

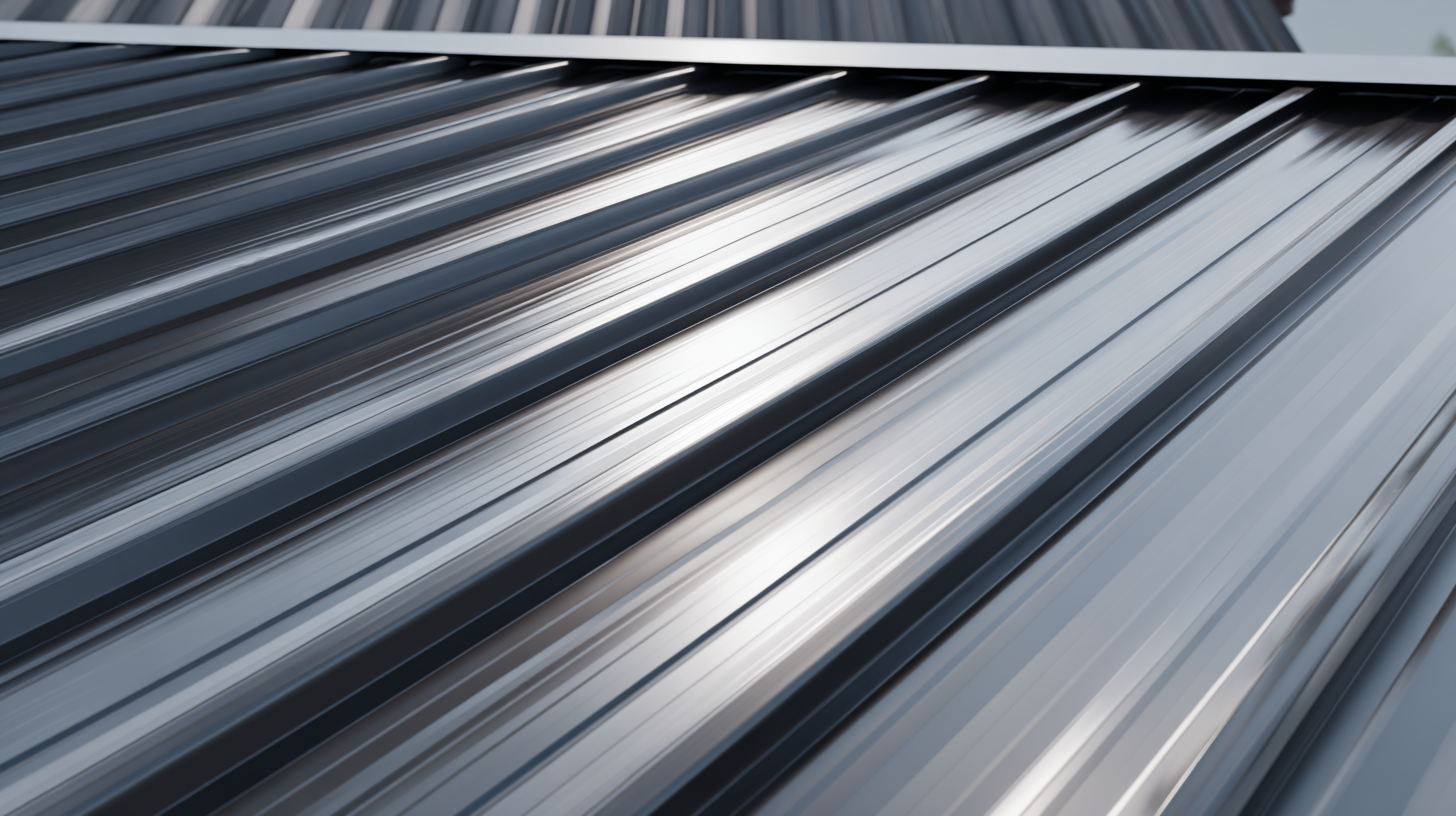

What Are Cladding Sheets and Their Main Purposes?

Cladding sheets are essential components in modern construction, serving both functional and aesthetic purposes. These sheets are typically made from various materials such as metal, wood, or composite materials and are primarily used to protect the structural integrity of buildings. By acting as a barrier against the elements, cladding sheets help prevent moisture ingress, which can lead to significant damage over time. Additionally, they contribute to the energy efficiency of buildings by providing insulation and reducing heating and cooling costs.

Beyond their protective functions, cladding sheets play a pivotal role in enhancing the visual appeal of a building. As urban landscapes evolve, the demand for innovative and attractive facades has increased. Cladding allows architects and builders to explore creative designs, reflecting both contemporary trends and historical influences. In cities like Shanghai, where rich architectural heritage coexists with modern developments, cladding sheets are instrumental in maintaining aesthetic continuity while ensuring that structures meet current safety and performance standards. This blend of functionality and design illustrates why cladding is a critical aspect of the construction industry today.

Types of Cladding Sheets: Pros and Cons for Your Project

When choosing cladding sheets for your project, it's essential to understand the various types available and their respective advantages and disadvantages. Among the most popular options are vinyl, wood, metal, fiber cement, and composite materials. Vinyl cladding is known for its affordability and low maintenance, making it a common choice for residential projects. However, its aesthetic appeal may fall short compared to natural materials. On the other hand, wood cladding offers a warm, natural look but requires regular maintenance to prevent rot and insect damage.

For those prioritizing sustainability, eco-friendly cladding options like recycled metal or bamboo are gaining traction. These materials not only reduce environmental impact but also provide unique aesthetic attributes. Fiber cement cladding combines durability with fire resistance, making it suitable for various climates, but it can be more costly upfront. Understanding these pros and cons will help you select the best cladding sheet that meets both your functional needs and design preferences for your project.

How to Choose the Right Cladding Material for Your Needs

Choosing the right cladding material for your needs is crucial to achieving both

aesthetic appeal and

functional performance in your building project.

Start by considering the environment where your structure is located. For areas with extreme weather conditions,

materials like fiber cement or metal cladding

can offer durability and resistance to moisture or temperature fluctuations.

Alternatively, if you're looking for a more traditional look,

wood cladding can provide warmth and charm, although it may require

more maintenance over time.

Next, think about the thermal efficiency and insulation

properties of different materials. Cladding can significantly impact energy consumption, so options with high

R-values, such as insulated panels,

can be beneficial in reducing heating and cooling costs.

Additionally, you'll want to consider the aesthetic aspects—colors, finishes, and textures—that align with your

design vision. Ultimately, striking the right balance between

durability,

energy efficiency, and

visual appeal will help you select the perfect cladding

material for your project.

Installation Process: Key Steps for Fitting Cladding Sheets

When it comes to fitting cladding sheets, understanding the installation process is crucial for achieving a professional finish. The key steps begin with proper surface preparation. Ensure that the surface is clean, dry, and free from any debris. This not only enhances adhesion but also prolongs the lifespan of the cladding. Next, measure and cut the sheets accurately to fit your designated area. Precision is essential to avoid any gaps or overlaps that could compromise the overall appearance.

**Tips:** Always use a level to ensure your first sheet is straight, as this will set the tone for the entire installation. It’s also wise to use a high-quality adhesive to secure the sheets, ensuring a durable bond that withstands moisture and time. Additionally, consider leaving a small gap between the edge of the cladding and any adjacent surfaces; this allows for expansion and contraction due to temperature changes.

Once the sheets are in place, you can finish them with appropriate trims and sealants to protect against weather elements. Regularly check seals and joints to maintain their integrity, especially in high-moisture areas. By following these steps and tips, you will ensure a smooth installation and enjoy the numerous benefits that cladding sheets offer.

10 Essential Facts About Cladding Sheet You Need to Know - Installation Process: Key Steps for Fitting Cladding Sheets

| Fact Number | Fact Description | Installation Step | Key Consideration |

|---|---|---|---|

| 1 | Cladding sheets provide insulation and aesthetic appeal. | Prepare the wall surface by cleaning and leveling. | Ensure the surface is dry to prevent moisture issues. |

| 2 | They can be made from various materials including metal and wood. | Cut cladding sheets to required dimensions. | Use proper cutting tools to avoid material damage. |

| 3 | Cladding can improve a building's energy efficiency. | Install a moisture barrier if needed. | Check local building codes for requirements. |

| 4 | Proper ventilation between the cladding and the wall is critical. | Fix the first panel securely to the wall. | Use level tools to ensure alignment and straightness. |

| 5 | Cladding enhances the durability of the underlying structure. | Continue installation, overlapping sheets as necessary. | Follow manufacturer's instructions for overlaps. |

| 6 | Insulated cladding sheets can significantly reduce heating costs. | Seal joints between sheets to prevent air leaks. | Use appropriate sealants for waterproofing. |

| 7 | Cladding can be customized in terms of color and finish. | Install finishing trims around edges for a clean look. | Choose trim that complements the cladding material. |

| 8 | Regular maintenance can prolong the life of the cladding. | Inspect installation periodically for issues. | Look for signs of wear, warping, or damage. |

| 9 | Cladding helps improve the acoustics of a building. | Apply a sound-dampening material if needed. | Consider the building’s location and noise exposure. |

| 10 | Different cladding types have varying installation methods. | Consult professional installers for complex projects. | Ensure compliance with safety standards during installation. |

Maintenance Tips: Keeping Your Cladding Sheets in Top Condition

Maintaining cladding sheets is essential for ensuring their longevity and functionality. Regular maintenance can significantly extend the life of your cladding, as evidenced by a study from the Building Research Establishment, which found that well-maintained cladding can last up to 40% longer than poorly maintained sheets. This underscores the importance of routine inspections and timely repairs, especially in areas prone to harsh weather conditions.

One crucial aspect of maintenance is ensuring that the cladding sheets are cleaned periodically to prevent the build-up of dirt, algae, and moisture. According to the National Apartment Association, nearly 80% of property owners who engage in regular cleaning report fewer maintenance issues. Additionally, using appropriate cleaning solutions that do not harm the cladding material can further enhance the sheets' durability. It's also advisable to inspect the seals and joints regularly, as even minor damage can lead to extensive repairs if left unaddressed. By adopting these maintenance tips, property managers can ensure that their cladding sheets remain in top condition, ultimately safeguarding their investment.

Maintenance Tips for Cladding Sheets

This chart illustrates essential maintenance tips for cladding sheets, including recommended cleaning frequency, inspections, repair instances, and coating application intervals.